PVC masana'anta

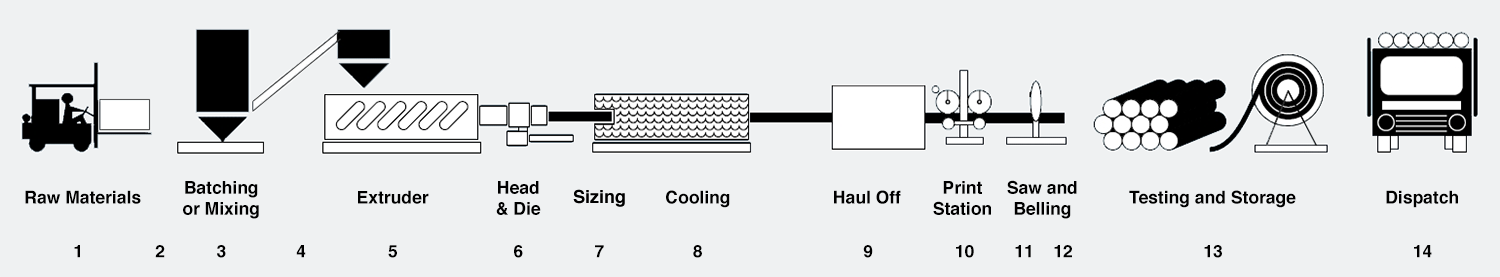

Ainihin, samfuran PVC an samo su daga raw PVC foda ta hanyar zafi da matsa lamba.Manyan matakai guda biyu da ake amfani da su wajen kera su ne extrusion don bututu da gyare-gyaren allura don kayan aiki.

Sarrafa PVC na zamani ya haɗa da haɓaka hanyoyin kimiyya sosai waɗanda ke buƙatar daidaitaccen iko akan masu canjin tsari.Kayan polymer shine foda mai gudana kyauta, wanda ke buƙatar ƙari na stabilizers da kayan aiki.Ƙirƙira da haɗawa sune matakai masu mahimmanci na tsari kuma ana kiyaye ƙayyadaddun ƙayyadaddun bayanai don shigowar albarkatun ƙasa, batching da haɗuwa.Ciyarwa zuwa extrusion ko injunan gyare-gyare na iya zama kai tsaye, a cikin nau'i na "bushewar gauraya", ko an riga an sarrafa shi cikin "haɗin gwiwa".

Extrusion

Polymer da additives (1) ana auna su daidai (2) kuma ana sarrafa su ta hanyar hadawa mai girma (3) don haɗa albarkatun ƙasa zuwa gauraya busassun gauraya iri ɗaya.Zazzabi mai gauraya na kusan 120°C ana samunsa ta zafi mai tauri.A matakai daban-daban na tsarin hadawa, abubuwan da ake ƙarawa suna narke kuma suna ci gaba da ɗaukar granules na polymer na PVC.Bayan an kai ga zafin da ake buƙata, za a fitar da gauraya kai tsaye a cikin ɗakin sanyaya wanda da sauri yana rage zafin jiki zuwa kusan 50 ° C, ta yadda za a iya isar da gauran zuwa matsakaicin ajiya (4) inda har ma ana samun daidaiton yanayin zafi da yawa.

Zuciyar tsari, extruder (5), tana da ganga mai kula da zafin jiki, wanda ke jujjuya madaidaicin "skru".Screws na zamani na zamani sune na'urori masu rikitarwa, an tsara su a hankali tare da jiragen sama daban-daban don sarrafa matsawa da raguwa, haɓakawa a cikin kayan, yayin duk matakan tsari.Tsarin juzu'i na tagwaye mai jujjuyawa wanda duk manyan masana'antun ke amfani da shi yana ba da ingantacciyar sarrafawa.

Ana amfani da busasshiyar PVC a cikin ganga da screws, wanda sannan canza busassun busassun zuwa yanayin "narke" da ake buƙata, ta zafi, matsa lamba da ƙarfi.A lokacin da yake tafiya tare da sukurori, PVC yana wucewa ta yankuna da yawa waɗanda ke damfara, daidaitawa da kuma fitar da rafin narke.Yankin ƙarshe yana ƙara matsa lamba don fitar da narke ta cikin kai kuma ya mutu saitin (6) wanda aka tsara bisa ga girman bututun da ake buƙata da halayen kwararar rafin narke.Da zarar bututun ya bar extrusion ya mutu, ana yin girmansa ta hanyar wucewa ta hannun rigar madaidaici tare da injin waje.Wannan ya isa ya taurare murfin PVC na waje kuma ya riƙe diamita na bututu yayin sanyayawar ƙarshe a cikin ɗakunan sanyaya ruwa mai sarrafawa (8).

Ana ja da bututun ta wurin aiki mai girma da sanyaya ta mai jan ko kashe (9) a akai-akai.Gudanar da sauri yana da mahimmanci sosai lokacin da ake amfani da wannan kayan aiki saboda saurin da aka ja bututun zai shafi kaurin bangon samfurin da aka gama.Dangane da bututun da aka haɗe da zoben roba, an rage saurin kashe bututun da ya dace don ƙara kauri a yankin soket.

Firin buga layi (10) yana yiwa bututun alama a tsaka-tsaki na yau da kullun, tare da tantancewa gwargwadon girman, aji, nau'in, kwanan wata, Daidaitaccen lamba, da lambar extruder.Zagi mai yankewa ta atomatik (11) yana yanke bututu zuwa tsayin da ake buƙata.

Injin ƙararrawa yana samar da soket a ƙarshen kowane tsayin bututu (12).Akwai nau'ikan soket guda biyu gabaɗaya.Don bututu mai haɗe-haɗe da zoben roba, ana amfani da maɗauri mai yuwuwa, yayin da kuma ana amfani da madaidaicin fili don ƙwanƙolin haɗin gwiwa.Bututun zobe na roba yana buƙatar chamfer akan spigot, wanda aka kashe ko dai a tashar gani ko sashin kararrawa.

Ana adana samfurin da aka gama a cikin wuraren riƙewa don dubawa da gwajin gwaji na ƙarshe da karɓa mai inganci (13).Ana gwada duk abubuwan samarwa kuma ana bincika su daidai da daidaitattun ƙa'idodin Australiya da/ko ga ƙayyadaddun mai siye.

Bayan dubawa da karɓa, ana adana bututun don jiran aika ƙarshe (14).

Don madaidaitan bututun PVC (PVC-O), tsarin extrusion yana biye da ƙarin tsarin haɓakawa wanda ke faruwa a ƙarƙashin ƙayyadaddun ƙayyadaddun ƙayyadaddun yanayin yanayin zafi da matsa lamba.A lokacin haɓakawa ne madaidaicin kwayoyin halitta, wanda ke ba da babban ƙarfin hali na PVC-O, ya faru.

Injection Molding

Ana yin kayan aikin PVC ta hanyar gyare-gyaren allura mai ƙarfi.Ya bambanta da ci gaba da extrusion, gyare-gyaren tsari ne mai maimaitawa, inda aka ba da "harbi" na abu zuwa ga wani mold a kowane sake zagayowar.

Abun PVC, ko dai a cikin busasshiyar foda foda ko nau'in fili na granular, ana ciyar da shi daga hopper da ke sama da sashin allura, cikin gidan ganga mai jujjuyawar juyawa.

Ana cajin ganga tare da adadin filastik da ake buƙata ta hanyar jujjuyawar juyawa da isar da kayan zuwa gaban ganga.An saita matsayin dunƙule zuwa “girman harbi” da aka ƙaddara.A lokacin wannan aikin, matsa lamba da zafi "plasticise" abu, wanda yanzu a cikin yanayin narkewa, yana jiran allura a cikin mold.

Duk wannan yana faruwa a lokacin yanayin sanyi na harbin da ya gabata.Bayan lokacin da aka saita ƙirar za ta buɗe kuma za a fitar da abin da aka ƙera daga ƙirar.

Sa'an nan kuma ya rufe da robobin da ke narke a gaban ganga a karkashin babban matsin lamba ta dunƙule a yanzu yana aiki azaman plunger.Filastik ta shiga cikin ƙirar don samar da dacewa ta gaba.

Bayan allura, caji yana farawa yayin da gyare-gyaren da aka ƙera yana wucewa ta yanayin sanyaya.

Lokacin aikawa: Juni-23-2022